GENERAL INFORMATION

GENERAL INFORMATION

CABINETRY

This PDF was last updated on 04/09/2024. Please redownload if you’re currently working from an older version.

GENERAL REQUIREMENTS:

All cabinetry to be plywood construction (no particleboard).

180 degree hinges, wrap hinge.

No blind corners:

All space below the corner of a kitchen countertop must be accessible from either of the adjacent cabinets, or by a special corner cabinet door.

No drawers larger than 18”.

KCMA certification preferred.

Hardware (pull) to be included in all cabinetry.

The cabinetry products in this section are shown as reference. Other cabinetry products that meet the requirements of the spec may be used.

Countertop Construction:

Post form (continuous, no visible joints).

Front Edge - Continuous, Double Round Over, 1 3/8" high (See Section Below).

Backsplash - Continuous one piece raises up wall with 1 1/8" return to wall (See Section Below).

Seal with foam all plumbing and electrical penetrations behind cabinetry.

Share the following form with installers to make sure new cabinetry meets POAH's requirements:

BOX CONSTRUCTION

BOX CONSTRUCTION

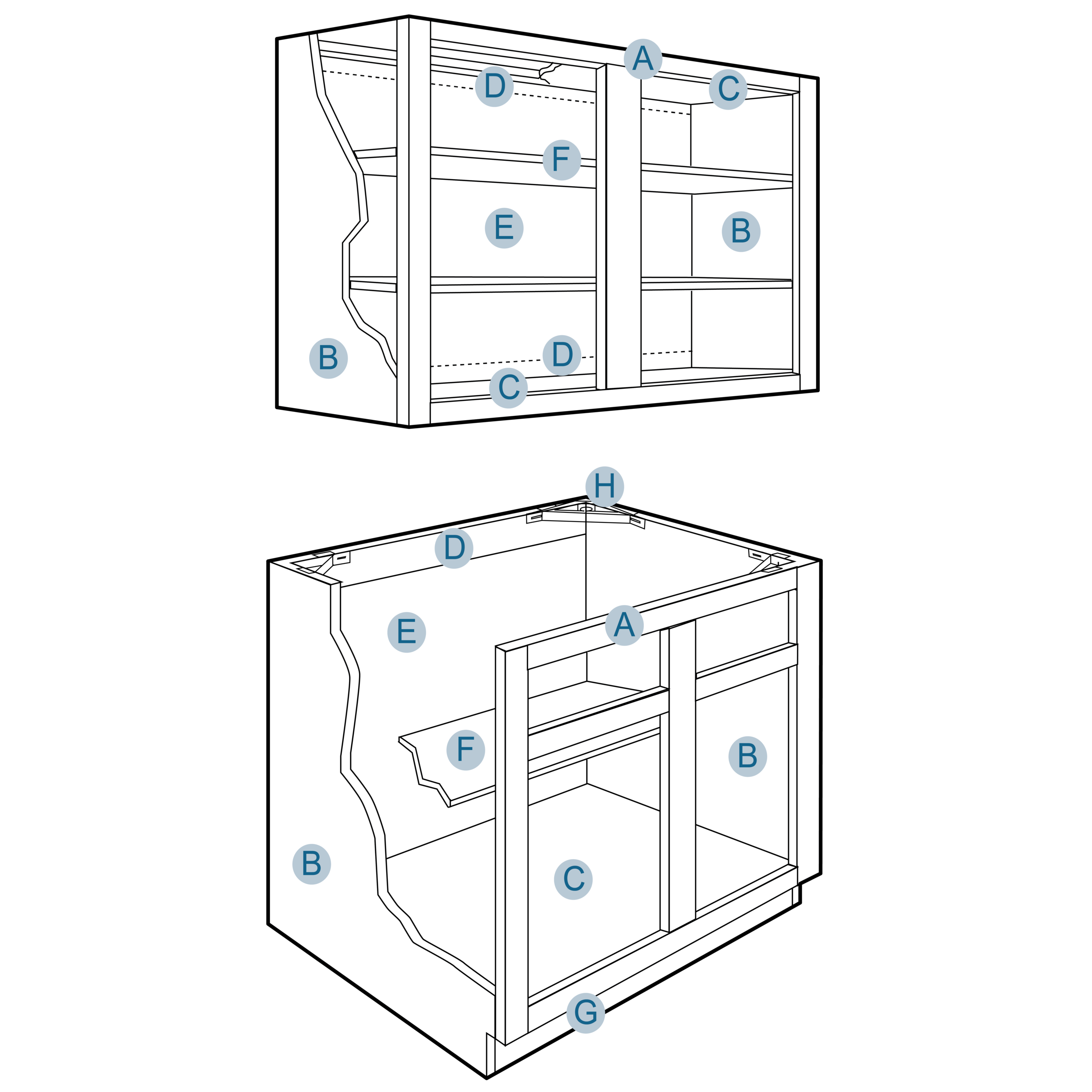

BOX CONSTRUCTION REQUIRED DETAILS:

A) FRONT FRAME: 3/4” solid hardwood or thermo-foil vinyl wrapped solid finger jointed lumber or LVL linear veneer lumber Bore and dowel/pocket screw construction frame joinery reinforced with glue/nails. Stiles 1 1/2” wide. Mulls 3” wide. Rails 1 3/4” wide. Stile and top and bottom rails dadoed to receive ends, tops, and bottoms.

B) END PANELS: Standard: Nominal 1/2” thick multi-ply birch veneer plywood dadoed to receive tops and bottoms, with wood grained or laminate on interior/exterior surfaces. All end panels are inserted into dado in face frame and recessed 3/16”.

C) TOP/BOTTOM PANELS: 1/2” thick multi-ply hardwood plywood. Tops and bottoms are set into grooved end panels and front rails glued and stapled. Bottoms are supported by 1/2” thick wood base composite panel.

D) HANGING RAILS: Wall cabinets have 1/2” thick x 2 7/8” multi-ply plywood hanging rail, running full cabinet width at top and bottom. Base cabinets have 1/2” thick x 2 7/8” wood based composite panel hanging rail running full cabinet width at top. Hanging rails are captured between end panels recessed behind.

E) BACK PANEL: 1/8” thick hardwood plywood Securely glued/stapled to end panels and hang rails. Back panels are fully captured on wall cabinets.

F) SHELVES: 5/8” thick multi-ply hardwood plywood, with hardwood veneer banded front edge. Shelves are adjustable in all standard wall and base cabinets.

G) TOE KICK: 4” high and recessed 3 3/8”.1/2” thick unfinished wood based composite panel captured between end panels. Finish should be covered with infill panel to match finish.

H) BASE CORNER BRACES: High impact, injection molded plastic.

I) DRAWERS: Nominal 1/2” thick multi-ply hardwood front, back, and sides. Drawer bottoms are nominal 1/4” thick multi-ply hardwood inserted into dado in front back and sides. All drawer parts glued and stapled together.

J) DRAWER GUIDES: High-quality epoxy coated steel, Cushion-Tec, side mounted guides, self adjusting in mounting brackets. Built-in stop, self-closing and stay-closed features with a 100 lb. rated load capacity.

COUNTERTOPS

COUNTERTOPS

COUNTERTOP REQUIRED DETAILS:

Plastic Laminate (Kitchen only):

- Suggested Laminate Manufacturers: Wilsonart or Formica.

- NEMA LD 3 compliant, HGP Grade, and minimum 1.0mm thickness.

- Countertop Construction:

- Post form (continuous, no visible joints).

- Front Edge - Continuous, Double Round Over, 1 3/8" high (See Section Below).

- Backsplash - Continuous one piece raises up wall with 1 1/8" return to wall (See Section Below).

- Side splash - square edged loose, installed between wall and counter, height to match back splash height.

- Substrate: Comply with ASTM D 1037.

- At Sink: Exterior grade plywood or phenolic resin.

- Particleboard: Compliance with ANSI A208.1 (Grade M-2 exterior

glue), 45-lb density and minimum 3/4” thick. - MDF: Compliance with ANSI A208.2 and minimum 3/4" thick.

- Provide BK-20 Backer Sheet if unsupported countertop area.

GRAPHIC OF POST FORM COUNTERTOP:

Solid Surface/ Vanity Top with Integral Sink (Bathrooms only):

- Suggested Manufacturers: Swanstone.

- Coordinate size with cabinetry manufacturer.

- Coordinate product with faucet. No open holes or plugs to be used.

- 2 gallon bowl capacity.

DOOR STYLES

DOOR STYLES

DOOR REQUIREMENTS:

Family properties: 3/4” thick solid wood door frames and drawer fronts.

Senior Properties: MDF center panels acceptable.

Standard reveal doors and drawer fronts.

SAMPLE DOOR PRODUCTS:

See Unit Finishes for style and color options. All cabinetry must meet all performance criteria. Use this Cabinetry Compliance Form for any deviations from these requirements.